For so many EHS professionals, individual performance is measured by what’s already happened. Incident rates, lost time, and compensation claims – these units are seen as the standard indication for the success or failure of EHS programs. As such, you’d be forgiven for thinking the organizations that outperform must just have better tools at their disposal to see these measures consistently improve…and you’d be half right.

Outperformers (organizations that consistently meet or exceed their goals) aren’t just looking in their rearview mirror. They’re using technology to help look ahead, shifting to a model that tracks leading safety indicators.

What are Lagging and Leading Safety Indicators?

Put simply; lagging indicators are outcome-based units of measure that have already happened.

- “How many safety incidents happened last year?”

- “How long is it taking staff to return to work after an injury?”

- “How many SIFs were reported by staff?”

These questions all use metrics that have happened, and are often benchmarked against industry averages.

These metrics are easy to quantify and benchmark, which is perhaps why they’ve become the default – but they’re inherently reactive. If you’re an EHS professional looking into incident rates, by the time you’ve measured and analyzed them, there could already be another incident to investigate; the damage is already done.

Leading indicators are different. They’re proactive, preventive, and predictive. They measure the activities and conditions that reduce risk before an incident occurs. OSHA defines them as metrics that “provide information about the effective performance of your safety and health activities”.

Examples include the percentage of employees completing safety training, the number of near-miss reports submitted, and the frequency of safety audits. These indicators don’t just reflect safety culture; they shape it.

In a Campbell Institute survey, 61% of EHS professionals said measuring leading indicators is “extremely important,” and another 28% said it’s “very important”. Yet many organizations still struggle to implement them consistently.

What the Outperformers Do Differently

If it wasn’t obvious by now; outperformers are primarily focused on leading indicators. However, they don’t just track leading indicators; they embed them into their operations. They understand that these metrics are not just data points, but levers for change.

For example, Cority customer NASA looked at the data being collected across their workforce to inform holistically, rather than silo data into individual departments. Their use of Industrial Hygiene monitoring enables tracking of industrial surveys and lab results designed to validate whether employees are enrolled in the correct exposure groups. However, NASA saw an opportunity to combine this data with worker health data, providing clinicians with knowledge of these exposure groups, allowing them to run additional testing, and even apply preventative treatments if required.

Getting Started with Leading Safety Indicators

Any time a ‘new idea’ is raised in EHS it can be met with resistance along the lines of, “this sounds like a big, daunting undertaking for an already stretched team.” However, it doesn’t have to be. Organizations that are mature enough to consistently track and analyze any metric are well on their way to using leading indicators.

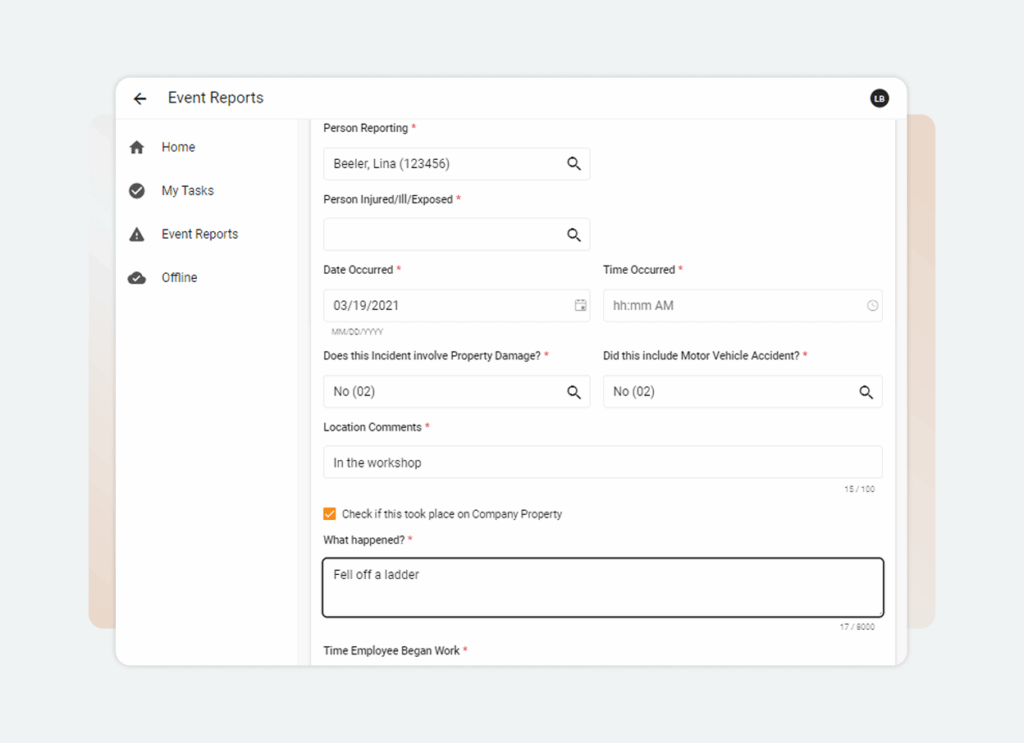

If an organization is far enough along the journey of digital transformation to be using a software tool to measure safety performance, it’s a simple enough change to focus on the leading indicators we’ve already mentioned here. It’s even entirely possible that an organization is already tracking these metrics and simply hasn’t begun focusing on them.

Either way – what’s the simplest way to begin focusing on leading safety indicators? The answer usually lies within organizational participation. Administrators can look at participation in training, the use of PPE, how many members of staff are reporting incidents, or the time between an incident being reported, and action being taken to address that hazard.

Organizations don’t need to overhaul their entire safety program overnight. But they do need to start. As the NSC’s Jonathan Thomas notes, “Metrics don’t drive change—people do.”

Moving Forward with Leading Safety Indicators

The difference between leading and lagging indicators isn’t just semantic. It’s strategic. Outperformers in EHS understand that leading safety indicators are the key to building resilient, proactive safety cultures. They don’t wait for incidents to tell them something’s wrong. They use data to stay ahead of risk; and that’s what sets them apart.