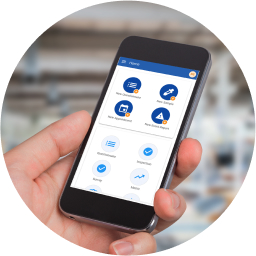

The Leader in Industrial Hygiene Software

Consistently ranked as the industry leader for industrial hygiene software solutions by independent analyst Verdantix, Cority combines the deepest subject matter expertise with the most comprehensive, configurable, and secure platform to help businesses manage their Industrial Hygiene programs with greater confidence and ease.